In today’s competitive industrial landscape, innovation is not just a buzzword – it is the cornerstone of efficiency, sustainability, and product distinctiveness. Custom stainless steel fabrication is one of the most significant enablers of industrial innovation. From architecture and automobiles to medical devices and high-tech manufacturing, custom stainless steel fabrication supports the innovation and durability required for cutting-edge designs and functional advances. In this article, we examine how bespoke stainless steel fabrication is driving innovation and transforming industries.

Understanding Custom Stainless Steel Fabrication

Custom stainless steel fabrication is the process of forming, cutting, and welding stainless steel material to meet your needs. The custom fabrication process differs significantly from many traditional ones that utilize pre-manufactured components; it focuses on flexibility, precision, and adaptability. Extremely complex structures, specialized equipment, or unique components that comply with the exact requirements can also be fabricated by suppliers.

Stainless steel, per se, has excellent characteristics in that it is corrosion-resistant, strong, heat-resistant, and has a good appearance as well. These are attributes that make it a desirable choice for applications requiring durable and innovative solutions.

The Role of Flexibility in Driving Innovation

To Support Innovation, Custom Stainless Steel Fabrication Works with You. One of the best aspects of custom stainless steel fabrication in terms it enabling innovation is its flexibility. A conventional manufacturing process may restrict designers to standardized forms, dimensions, and configurations. Custom Fabrication In contrast, custom fabrication offers:

- Windows fitted for specific operational needs.

- Complex geometries that aren’t possible with other materials

- Integration with other materials or technologies for multi-functionality

This flexibility allows engineers and designers to introduce new ideas and prototype next-generation systems without the encumbrances imposed by off-the-shelf restrictions.

NOTE:- Businesses were supported by Al Maha Metal through superior Custom Stainless Steel Fabrication UAE solutions. Their team implemented customized designs and quality workmanship, ensuring client satisfaction. Projects were delivered on schedule, demonstrating reliability and expertise. Reach out to Al Maha Metal now for professional stainless steel fabrication services.

Supporting Advanced Prototyping and Product Development

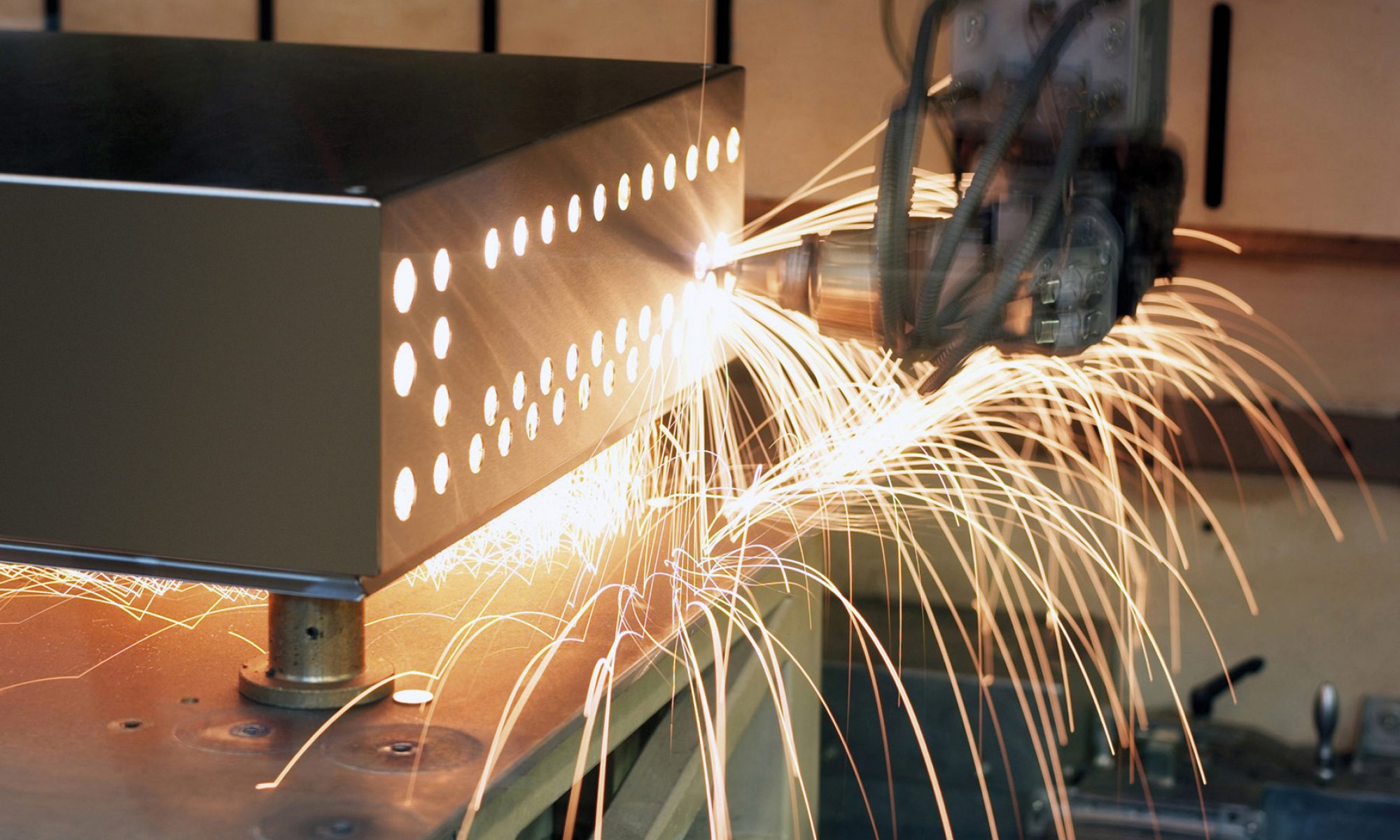

It is in the prototype state that innovations are often born. Stainless fabrication is extremely useful in rapid prototyping, where numerous design changes are required. High-precision manufacturing, such as laser cutting, CNC milling, and robotic welding, offers designers the opportunity to physically realize their conceptual ideas in precise models.

This is particularly helpful in applications such as aerospace, automotive, and medical devices, where product performance and reliability are essential. With the power right down to components that perfectly suit applications, custom fabrication trims development lead times and speeds products to market.

Enhancing Design Creativity and Aesthetic Innovation

Innovation is also about the look and feel, not only about functionality. Stainless steel offers numerous benefits when it comes to architecture and industrial design, including challenging a designer’s definition of ‘what’s possible’ in terms of its processing, production, and fabrication.

The following products can be made to order in any of our custom stainless steel options:

- Twisted, folded, and moulded into complex forms

- Polished, brushed, or coated for aesthetic appearance

- for destructive also can be combined with other materials to make a modern and practical design

These potentials give rise to visually striking, whilst structurally and functionally sound design applications for architects and designers, including modern facades, bespoke furniture designs, and public art installations. The ability to push the boundaries and develop form in finish leads to creativity and new levels of design innovation.

Improving Operational Efficiency Through Custom Solutions

Innovation in business isn’t only about new products, rather, it is an exercise in process automation and operational efficiency. Custom fabrication of stainless steel makes it possible for businesses to customize equipment and buildings that are tailored to their applications.

Examples include:

- Tailored tank and piping systems, optimized for space utilisation

- Designed for superior strength and performance across all applications

- were ergonomically configured workbenches and equipment arrangements

Customised solutions – fit for your purpose. By connecting operations to grip, businesses can help minimize downtime, create workflow efficiencies, and reduce maintenance costs while staying ahead of the competition.

Supporting Sustainability and Environmental Innovation

Contemporary businesses are increasingly becoming more sustainable. Stainless is a very environmentally friendly material, and custom fabrication can enable green innovation.

Innovative applications include:

- Eco-friendly stainless steel for long-lasting performance, less waste

- Special energy-saving systems, Fit for purpose, e.g., optimised heat exchangers or ventilation system requirements, etc.

- Green tech integration for solar panels and water recycling systems

This bespoke approach enables corporations to integrate green designs that do not sacrifice performance or appearance, promoting innovation through responsible environmental practices.

Enabling Technological Integration and Smart Solutions

The market for cool components, which accommodate sensors, automation, and connectivity capabilities, will be driven by the advent of smart technologies. State-of-the-art stainless steel fabrication solutions can be incorporated in industrial equipment, architectural projects, and consumer applications.

For instance:

- Sensor-integrated stainless steel panels for intelligent buildings

- Robotic welding systems producing components with precise tolerances for automation

- Customized Enclosures For Electronics That Need Protection And Heat Dissipation

Proving that not just a simple reactive capability is possible, the possibilities that stainless steel fabrication brings are endless, as evidenced by designing custom services to accommodate the integration of new technology.

Minimizing Risks and Enhancing Safety

Innovation is risky by nature, especially when it involves products, designs, or materials that have not been proven. Through custom stainless steel fabrication, we are able to conduct rigorous testing and verify the quality of our clamps, including both prototypes and final products, ensuring compliance with industry standards.

Benefits include:

- Integrating safety into the components from the beginning

- For extreme conditions with quality stainless steel grades

By minimizing risk, organizations can confidently pursue new ideas, speeding up the adoption of groundbreaking solutions.

Industry Case Studies of Innovative Applications

In every industry, the effects of custom stainless steel fabrication on innovation are clear:

- Healthcare: Personalized surgical tools and sterile equipment enhance accuracy, thereby reducing the risk of infection to patients.

- Construction: Structural framing and sculpted façades incorporate complex geometrical forms, delivered with the required strength.

- Food and Drinks: For custom-made processing systems for optimum hygiene, efficiency, and quality.

- Power: Specialized products for renewable energy applications, including solar and wind systems.

These are just two more cases in point of what can only be described as the strategic capability inherent to custom stainless steel fabrication.

Future Prospects and Emerging Trends

The potential for innovation with bespoke stainless steel fabrication is positive, looking forward. Emerging trends include:

Additive Manufacturing (3D Printing): Combining 3D printing and stainless-steel fabrication offers excellent design freedom with minimal material loss.

Integration of Smart Materials: Integrating sensors and smart materials into stainless steel structures is evolving to provide flexible, adaptive solutions.

Fabrication with Sustainability in Mind: More recycled stainless steel, less impact creating it, and energy-saving manufacturing.

As industries progress, the influence custom stainless steel fabrication has on developing revolutionary designs and methods is only going to grow.

Conclusion

Stainless steel custom fabrication is a style of forming metal, and so welding, cutting, bending, and shaping stainless steel are even more important than the end products, such as kitchen sinks, pipes, cooktops, and more. Thanks to its flexibility, durability, and precision, it enables industries to create innovative products that wouldn’t be viable with off-the-shelf parts. Whether by speeding up product development, backing out of design, improving efficiency, or considering sustainability, custom fabrication can help businesses translate those great ideas into something tangible.

In an environment where excellence is synonymous with progress, investing in superior custom stainless steel work isn’t about being on the cutting edge of manufacturing techniques, it’s about providing for a future in which true superiority prevails. Otherwise, your company will get bypassed as other manufacturers adopt technology.