In today’s competitive manufacturing world, precision, efficiency, and adaptability are crucial for producing high-quality components. Industries ranging from aerospace and automotive to medical and electronics rely heavily on custom CNC machining services to meet their unique production requirements. With technology advancing rapidly, CNC processes have become indispensable in creating complex, accurate, and durable parts for businesses worldwide.

This article explores the benefits, applications, and growing importance of custom CNC machining services, while also highlighting how they integrate with other advanced techniques like CNC prototyping services, CNC milling and turning services, and low volume CNC machining.

What are Custom CNC Machining Services?

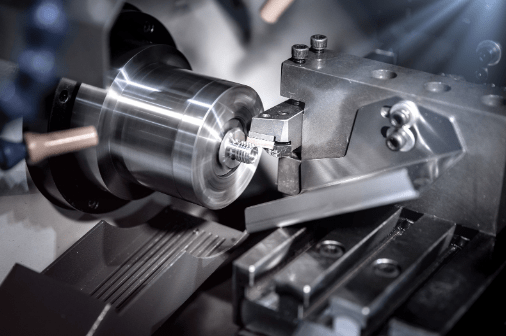

Custom CNC machining services provide manufacturers with tailored solutions to produce components according to specific design and performance requirements. Unlike conventional machining methods, CNC technology uses computer-controlled precision tools that deliver unmatched accuracy and repeatability.

By leveraging custom CNC machining services, industries can create prototypes, specialized parts, and final products that align with complex designs and tight tolerances. This adaptability makes CNC a cornerstone of modern production.

The Role of CNC Machining Services in Modern Industry

The backbone of many sectors lies in efficient CNC machining services. These services allow companies to manufacture parts quickly without compromising accuracy. From simple shapes to intricate geometries, CNC technology ensures consistency across multiple production runs.

One of the greatest strengths of custom CNC machining services is their ability to adapt to a variety of materials, including metals like aluminum, stainless steel, and titanium, as well as plastics. This versatility enables businesses to create products that are durable, lightweight, and designed for specific applications.

Advantages of Custom CNC Machining Services

1. Precision and Accuracy

The most compelling advantage of custom CNC machining services is the exceptional level of precision they provide. With advanced software integration, the margin of error is reduced to a minimum, ensuring high-quality output.

2. Cost-Effectiveness for Low Batches

For companies that need low volume CNC machining, CNC technology proves highly economical. Instead of investing in costly mass production setups, businesses can achieve their goals with smaller, customized runs while maintaining cost efficiency.

3. Flexibility in Design

Custom CNC machining services enable engineers to experiment with complex geometries and intricate designs. Whether for prototypes or final components, CNC allows for easy modifications and fine-tuning.

4. Speed of Production

Combined with CNC prototyping services, CNC machining accelerates the product development cycle. Rapid prototypes can be produced in a matter of hours, significantly reducing time-to-market.

Integrating CNC Prototyping Services

Before mass production, many industries rely on CNC prototyping services to test their designs. This phase ensures that the final product will perform as expected, avoiding costly errors later.

By combining prototyping with custom CNC machining services, businesses can refine their concepts and bring innovative products to life with confidence. The precision and repeatability of CNC make it an excellent choice for creating prototypes that mirror final production quality.

CNC Milling and Turning Services: Complementing Custom CNC Machining

While custom CNC machining services cover a broad range of processes, CNC milling and turning services remain the most popular techniques.

-

CNC Milling: This process involves cutting and drilling materials using rotating tools, perfect for intricate designs and flat surfaces.

-

CNC Turning: This technique uses a lathe to rotate the workpiece against cutting tools, ideal for cylindrical or symmetrical parts.

Together, CNC milling and turning services expand the possibilities of manufacturing, ensuring parts of varying complexities can be created with ease.

The Importance of Low Volume CNC Machining

For startups and companies developing specialized products, low volume CNC machining is invaluable. It bridges the gap between prototyping and full-scale production, allowing businesses to test market viability without large investments.

By combining low volume CNC machining with custom CNC machining services, manufacturers can deliver tailored solutions that meet specific demands while maintaining cost efficiency.

Precision Machining Services for Critical Applications

When industries like aerospace, defense, and medical devices require uncompromised quality, they turn to precision machining services. These services emphasize tight tolerances and superior finishing.

Integrating precision machining services with custom CNC machining services ensures that the parts not only meet but exceed industry standards. This is particularly crucial for components where performance and safety are non-negotiable.

Applications of Custom CNC Machining Services

Aerospace and Automotive

Aircraft components, engine parts, and lightweight structural elements are often created through custom CNC machining services, ensuring reliability under extreme conditions.

Medical Devices

The medical field relies on CNC technology for surgical instruments, implants, and diagnostic equipment where precision saves lives.

Electronics

CNC enables the production of housings, connectors, and heat sinks with exact dimensions required for electronics.

Industrial Equipment

Heavy machinery and manufacturing tools benefit from custom CNC machining services, ensuring durability and performance in demanding environments.

Future of Custom CNC Machining Services

As digital manufacturing evolves, custom CNC machining services are expected to integrate more with automation, artificial intelligence, and 3D printing. This fusion will make the process even more efficient, cost-effective, and capable of handling complex projects with ease.

For businesses, the growing reliance on custom CNC machining services means more opportunities to innovate while minimizing production risks.

Conclusion

The significance of custom CNC machining services in today’s industrial landscape cannot be overstated. From improving accuracy and reducing production time to enabling CNC prototyping services and low volume CNC machining, these services shape the way industries design and manufacture products.

By embracing CNC machining services, companies can ensure their components meet the highest standards of quality and performance. Whether through CNC milling and turning services, prototyping, or precision machining services, the future of manufacturing continues to be defined by innovation, adaptability, and excellence.