In today’s competitive manufacturing world, CNC machining services have become the backbone of product development, precision engineering, and efficient production. From creating high-accuracy prototypes to delivering low-volume production runs, these services ensure businesses can achieve consistency, scalability, and quality in their projects. Whether for aerospace, automotive, medical, or consumer products, industries around the globe rely on CNC machining to bring concepts to life with unmatched precision.

This article explores the role, benefits, and applications of CNC machining while highlighting the specialized solutions available to meet diverse industrial needs.

Understanding CNC Machining Services

CNC machining services use computer numerical control (CNC) to automate manufacturing processes. This technology translates digital CAD designs into precise tool paths that guide cutting, drilling, milling, or turning machines. The result is a highly accurate, repeatable, and efficient production process capable of delivering parts with tight tolerances.

By integrating advanced software with high-performance equipment, CNC machining offers manufacturers faster turnaround, reduced errors, and the flexibility to produce both simple and complex components.

Benefits of CNC Machining Services

1. Unmatched Accuracy and Consistency

One of the defining features of CNC machining services is the ability to deliver parts with extreme precision. Modern CNC machines can achieve tolerances within microns, ensuring consistency even across multiple production runs.

2. Efficiency in Production

Automated operations reduce the chances of human error while speeding up manufacturing. Whether it’s producing prototypes or large-scale runs, CNC ensures efficiency without compromising on quality.

3. Material Versatility

CNC technology is compatible with a wide range of materials, including metals like aluminum, stainless steel, titanium, as well as plastics, composites, and specialty alloys. This versatility makes it an ideal choice for industries with diverse material requirements.

4. Scalability and Flexibility

From low volume CNC machining to full-scale mass production, the adaptability of CNC allows manufacturers to handle projects of different sizes without delays or quality issues.

Custom CNC Machining Services for Unique Needs

Every project is different, and custom CNC machining services are designed to meet those unique requirements. Whether it’s a prototype for testing or a tailored part with specific geometries, customization ensures that businesses get exactly what they need.

Custom solutions are particularly valuable in industries such as aerospace or medical technology, where precision and compliance with strict standards are critical. By leveraging customization, manufacturers can create components with complex geometries and exact specifications.

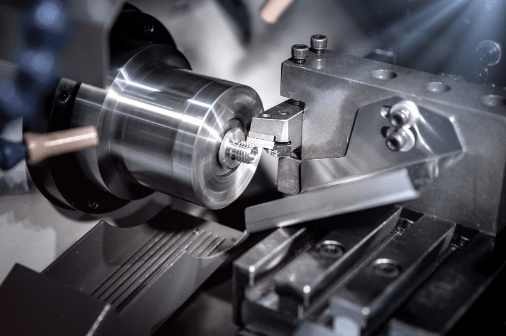

CNC Milling and Turning Services

Among the most widely used processes in machining are milling and turning. Together, they form the backbone of many production lines.

CNC Milling

CNC milling uses rotary cutters to remove material from a workpiece, producing precise shapes, slots, and holes. This process is ideal for parts that require complex 3D geometries.

CNC Turning

In turning, the workpiece rotates while a cutting tool shapes it. This process is efficient for creating cylindrical parts, threads, and high-symmetry designs.

By combining both processes, CNC milling and turning services offer comprehensive solutions for manufacturing a wide variety of components, from automotive shafts to aerospace brackets.

Low Volume CNC Machining for Flexibility

Not all projects require large-scale production. Many industries demand smaller runs for testing, product development, or niche applications.

Low volume CNC machining bridges the gap between prototyping and mass production. It enables companies to validate designs, test functionality, and make improvements without committing to expensive large-scale manufacturing. For startups and innovators, this option provides the flexibility to bring products to market quickly while managing costs effectively.

CNC Prototyping Services

Innovation often begins with a prototype. CNC prototyping services allow businesses to transform digital designs into tangible parts for testing and evaluation.

Prototypes play a crucial role in identifying design flaws, testing fit and function, and ensuring the end product meets requirements before scaling production. By relying on CNC technology, prototypes can be produced quickly with the same level of precision as final parts, ensuring accuracy and reliability throughout the development process.

Precision Machining Services: Meeting Industry Standards

In sectors such as aerospace, defense, and healthcare, there is no room for error. This is where precision machining services stand out. These services emphasize the highest standards of accuracy, ensuring every detail aligns with exact specifications.

From surgical instruments to aerospace turbine components, precision machining guarantees reliability and safety in mission-critical applications. It’s this level of quality that has positioned CNC machining as a trusted solution across industries.

Applications of CNC Machining Services

CNC machining is integral to numerous industries, each benefiting in unique ways:

-

Aerospace: Production of lightweight, high-strength components.

-

Automotive: Manufacturing engine parts, prototypes, and custom components.

-

Medical: Precision tools, implants, and devices for critical healthcare applications.

-

Electronics: High-accuracy housings, connectors, and circuit components.

-

Consumer Products: Durable, customized parts for household and industrial use.

By offering reliability and adaptability, CNC machining services provide the foundation for innovation across these sectors.

Future of CNC Machining Services

The future of CNC machining is shaped by automation, artificial intelligence, and advanced materials. Integration with Industry 4.0 technologies, such as IoT-enabled monitoring and predictive maintenance, is making CNC even more efficient and cost-effective.

Additionally, hybrid approaches that combine CNC with additive manufacturing (3D printing) are revolutionizing how products are designed and produced. These innovations ensure that CNC machining services will continue to evolve, delivering even greater value to industries worldwide.

Why Choose Professional CNC Machining Services?

Partnering with experts in machining provides businesses with access to advanced equipment, experienced engineers, and streamlined processes. Professionals ensure:

-

Faster turnaround times.

-

Guaranteed quality assurance.

-

Cost-effective solutions for both prototypes and production runs.

-

Comprehensive support from design to delivery.

Whether you need custom CNC machining services, CNC prototyping services, or low volume CNC machining, choosing the right partner ensures success in today’s fast-paced market.

Conclusion

CNC machining services have become essential for businesses aiming to achieve precision, efficiency, and flexibility in manufacturing. From CNC milling and turning services to precision machining services, the versatility of CNC technology supports innovation across multiple industries. By offering custom CNC machining services, rapid prototyping, and small-batch production, manufacturers can meet evolving demands with confidence.

For companies looking to stay competitive, investing in professional CNC machining solutions ensures that every part, prototype, or product exceeds expectations.