In the evolving world of manufacturing, Custom CNC Turning Services play a critical role in creating components that demand precision, durability, and speed. From aerospace to medical devices, industries across the globe rely on these services to meet strict requirements and achieve flawless production outcomes. By blending advanced technology with automated processes, Custom CNC Turning Services set the standard for modern machining.

Why Custom CNC Turning Services Are Essential

Unlike traditional methods, Custom CNC Turning Services provide unmatched consistency. Once a program is set, CNC machines replicate the same part with zero variation, making them invaluable for large-scale production and specialized projects.

Key benefits include:

-

High repeatability

-

Shorter lead times

-

Lower production costs

-

Greater design flexibility

For businesses that need to maintain a competitive edge, Custom CNC Turning Services are no longer optional—they are essential.

CNC Turning: The Foundation of Modern Machining

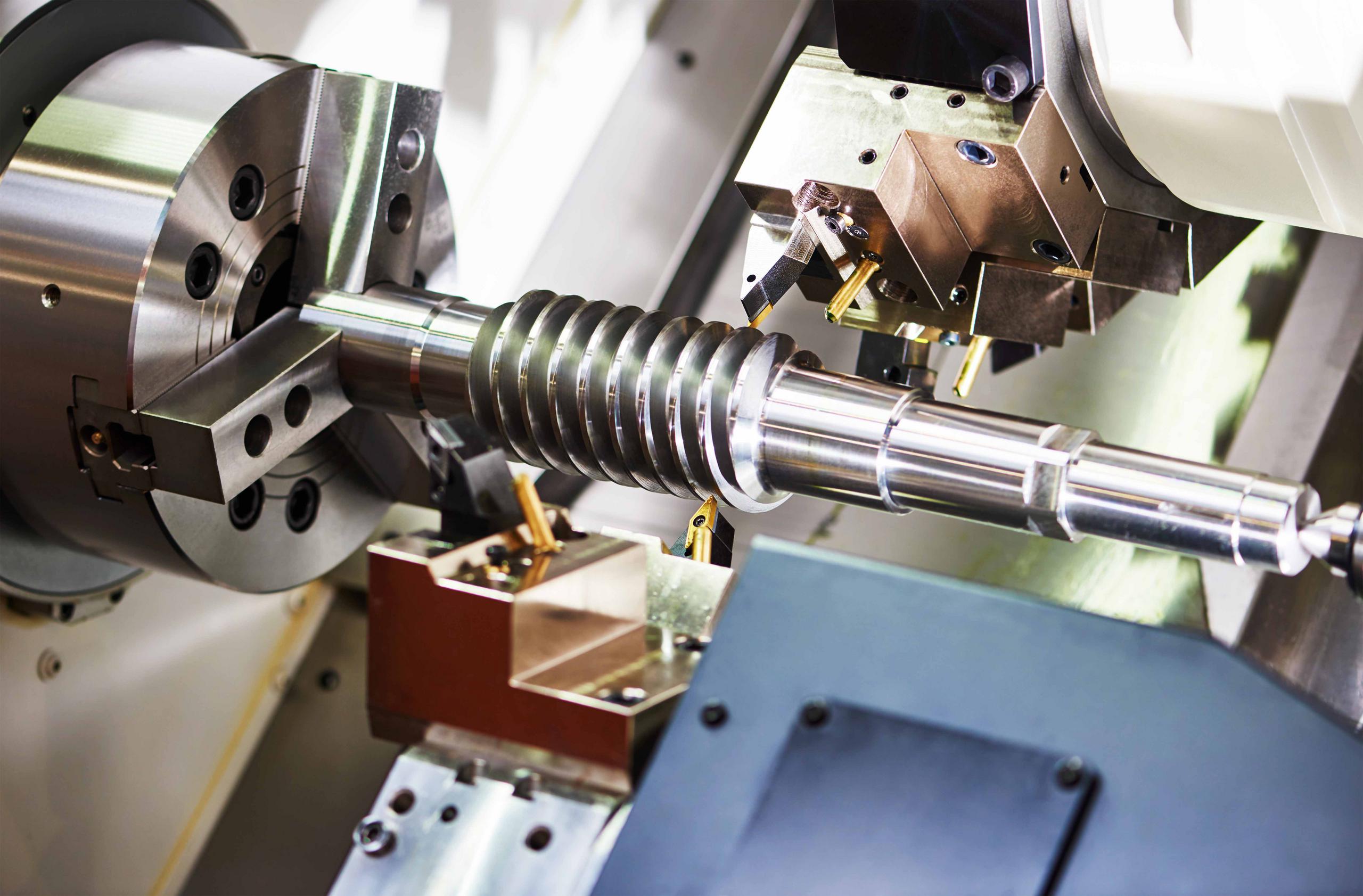

A core element of Custom CNC Turning Services is CNC turning, where the workpiece rotates while cutting tools shape it. CNC turning is perfect for producing round or cylindrical components such as pins, shafts, and bushings.

With CNC turning, manufacturers achieve tighter tolerances, consistent finishes, and the ability to handle both small and large production runs. This makes it one of the most widely adopted machining processes today.

Precision Turning for Critical Industries

When accuracy matters most, precision turning ensures that every component is crafted to exact specifications. Within Custom CNC Turning Services, precision turning eliminates inconsistencies and creates parts that fit perfectly into complex assemblies.

Industries such as aerospace, automotive, and healthcare demand components that cannot afford even the smallest deviation. By leveraging precision turning, companies achieve higher reliability and product performance.

Metal Turning for Strength and Durability

Another key part of Custom CNC Turning Services is metal turning. Whether it’s stainless steel, titanium, aluminum, or brass, metal turning allows for the production of durable, high-strength parts.

From automotive engines to heavy industrial equipment, metal turning creates components designed to withstand demanding conditions. It ensures strength without sacrificing accuracy, making it indispensable across manufacturing sectors.

Advanced Lathe Services in CNC Machining

Modern lathe services are far more advanced than traditional manual lathes. Within Custom CNC Turning Services, CNC lathes are equipped with software-driven controls and cutting-edge tooling, allowing manufacturers to produce parts with exceptional detail.

Lathe services today provide:

-

Complex geometries

-

Smooth finishes

-

Faster production speeds

-

Greater efficiency

By integrating CNC technology into lathe services, industries now achieve outcomes that were once impossible.

Custom Machining for Unique Requirements

Not every part is standard. That’s why custom machining is a critical part of Custom CNC Turning Services. When businesses require prototypes, one-off components, or specialized designs, custom machining makes it possible to deliver exactly what is needed.

From experimental parts to intricate assemblies, custom machining ensures flexibility while maintaining the high standards associated with CNC technology.

Advantages of Custom CNC Turning Services

1. Consistency

Every component produced maintains the same quality standards, batch after batch.

2. Speed

Automation shortens production times, enabling faster delivery.

3. Material Versatility

CNC turning, precision turning, and metal turning cover a wide range of metals and plastics.

4. Cost Efficiency

Less waste and fewer errors reduce overall costs.

5. Scalability

From small runs to mass production, Custom CNC Turning Services adapt to demand.

Applications Across Industries

-

Aerospace: Lightweight yet strong components made possible with metal turning and precision turning.

-

Medical: Reliable surgical instruments and implants manufactured using custom machining.

-

Automotive: High-volume shafts, fasteners, and gears produced with CNC turning and lathe services.

-

Electronics: Small-scale, intricate parts that require the precision of Custom CNC Turning Services.

The Future of Custom CNC Turning Services

Technology continues to transform Custom CNC Turning Services. AI-powered software, IoT-enabled monitoring, and predictive maintenance are already improving efficiency and accuracy. In the future, manufacturers can expect even greater levels of automation, ensuring higher productivity and fewer errors.

Companies that adopt these innovations will position themselves as leaders in manufacturing excellence.

Conclusion

Custom CNC Turning Services represent the future of precision manufacturing. Through the integration of CNC turning, precision turning, metal turning, lathe services, and custom machining, businesses gain the ability to produce components with unmatched accuracy and efficiency. For companies seeking growth, efficiency, and long-term success, investing in Custom CNC Turning Services is not just beneficial—it’s essential.